What Is a Jersey Barrier? – Definition, Materials, Purpose, and Origin of the Name

A Jersey barrier (also called a Jersey wall or concrete median barrier) is a rigid or semi-rigid barrier typically placed between traffic lanes, around construction zones, or in other areas where vehicle separation or protection is required. It is designed to redirect errant vehicles, reduce the severity of crashes, and prevent crossover accidents.

Materials include reinforced concrete or heavy‐duty plastic (often rotomolded or injection molded polyethylene/polypropylene) that can be water - or sand-filled. Plastic versions are portable and modular; concrete versions are permanent or semi-permanent.

The term “Jersey barrier” comes from its origin in the state of New Jersey: in the mid-1950s, engineers collaborated on a barrier shape that would redirect vehicles safely rather than simply stop them abruptly, reducing both cross-median crashes and rollover risk.

How Does a Jersey Barrier Work?

A Jersey barrier's functionality is rooted in its geometry, mass, and placement. Key operational principles include:

- Safety shape / sloped profile: One or more sloped faces (lower slope and upper slope) allow the vehicle tires to ride up slightly, lifting the vehicle and changing trajectory.

- Lift-and-redirect principle: Rather than absorbing all the impact or stopping the vehicle, the geometry causes the vehicle to be gently redirected back into its travel lane or away from oncoming traffic.

- Energy absorption: Concrete barriers use their mass; the barrier's rigidity plus its mass absorbs kinetic energy. Plastic, water-filled barriers also absorb energy via deformation, ballast (water/sand), and, for heavy collisions, by moving or rotating slightly.

- Crossover prevention: By preventing vehicles from crossing into opposing traffic lanes or medians, barriers reduce severity of potential head-on crashes.

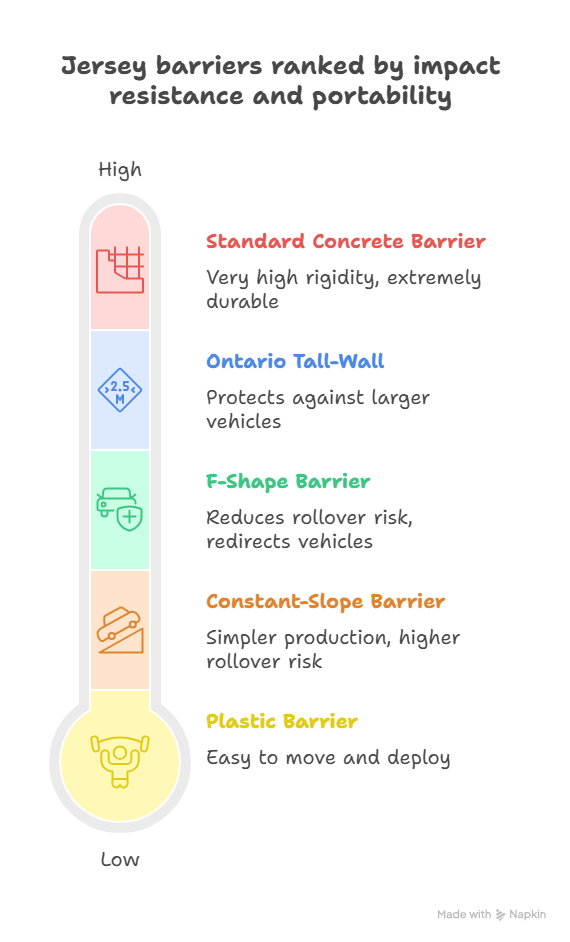

Types and Variations of Jersey Barriers

Here are some of our common profiles, heights, and materials, with specific product examples.

Standard Concrete Barrier (Original Jersey Profile)

- Height: 32 in

- Base width: 24 in

- Material: precast concrete, often reinforced with steel.

- Characteristics: very high rigidity, extremely durable, capable of handling high-speed vehicle impacts; heavy (often 3,000 to 4,000 lbs for a 10-foot unit), so it requires heavy equipment for installation. (Statistic: “A standard 10′ precast Jersey barrier weighs 3,000-4,000 lbs” emphasizes that point.)

- Use: permanent medians, highway dividers.

F-Shape Barrier

- Modified lower slope compared to the original Jersey profile.

- Improved in reducing rollover risk while performing similarly in redirecting vehicles.

- Often adopted in modern highway safety projects where rollover risk is a concern (especially for passenger cars and lighter vehicles).

Ontario Tall-Wall

- Taller barrier, typically 42 in height.

- Designed to better protect against intrusion by larger vehicles — trucks, buses, tall SUVs.

- Provides greater containment for high centre-of-gravity vehicles.

Constant-Slope (Texas) Barrier

- Single continuous slope (from base to top) rather than multiple slope sections.

- Simpler to produce and sometimes cheaper, but may have higher rollover risk under certain impact angles.

Plastic (Water-Filled) Barriers

These are usually made from polyethylene or polypropylene, are hollow, and are filled with water or sand for ballast. When empty, they are lightweight for transport and placement, then filled to achieve weight and stability.

Characteristics:

- Easier to move, store, and deploy than concrete.

- Less impact resistance compared to concrete, especially for high-speed, heavy-vehicle crashes, but good performance for lighter vehicles or lower speeds zones.

- Cost advantages for temporary installations, construction zones, and event crowd control.

Product examples from Epic Solutions:

Here are specific plastic Jersey barrier models, with dimensions, weight, and approximate costs (USD), to illustrate the range:

|

Product |

Height × Length × Width |

Empty weight / Key features |

Approx MSR Price* |

|

Plastic Jersey Barrier 32″ H × 72″ L |

32 in × 72 in × ~18–24 in |

Crash-test rated, rotationally molded plastic, heavy duty; empty weight moderate before filling. |

$274.00 |

|

Plastic Jersey Barrier 42″ H × 72″ L (100 lb empty) |

42 in × 72 in |

Taller height, more ballast needed; improved protection for larger vehicles. |

$359.00 |

|

Plastic Jersey Barrier 24″ H × 96″ L |

24 in × 96 in × ~16-width |

Lower profile, longer span; useful for lower speed zones or visual separation. |

$199.99 |

|

Stacking Jersey Barrier 32″ H × 48″ L |

32 in × 48 in × ~16 width; ~50 lb empty |

Stackable for storage; modular; useful in mixed uses when smaller units are needed. |

$169.99 |

|

Plastic Jersey Barrier 31″ H × 120″ L |

31 in × 120 in |

Very long unit; for large spans where fewer joints are desirable. |

$455.00 |

|

Plastic Jersey Barrier 42″ × 96″ (150 lb empty) |

42 in × 96 in |

Heavy duty, near Ontario Tall-Wall height; greater mass when filled. |

$510.64 |

*MSRP = Manufacturer's Suggested Retail Price, before shipping, filling, etc.

These products illustrate how plastic Jersey barriers can approach similar heights and spans to concrete versions, though with different behavior in impact and stability.

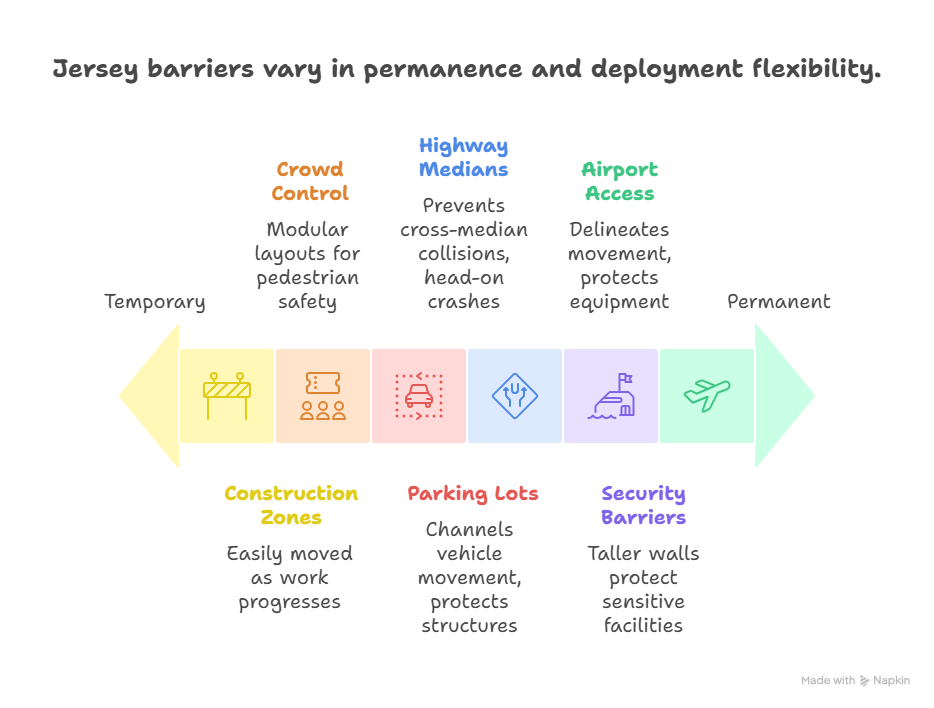

Applications and Use Cases

Jersey barriers are used in many settings; the correct choice depends on speed, traffic type, permanence, and safety goals.

- Highway Medians: Permanent or semi-permanent concrete barriers to prevent cross-median collisions and head-on crashes.

- Construction and Work Zones: Temporary plastic units that can be moved as the work progresses.

- Parking Lots: Plastic or low-profile concrete units to channel vehicle movement and protect structures.

- Crowd Control & Events: Plastic barriers are useful where pedestrian safety, temporary segmentation, or modular layouts matter.

- Security Barriers / Perimeter Protection: Taller walls (e.g., Ontario Tall-Wall) or concrete barriers in sensitive facilities; plastic versions with fence toppers also used in less permanent deployments.

- Airport or Access Control Areas: Lower profile plastic barriers (e.g. 24-in, 10-in models) used to delineate movement, protect structures or equipment, or enhance visual separation.

Installation, Cost, and Maintenance

Installing and maintaining Jersey barriers requires careful planning. Factors such as barrier weight, site conditions, and intended duration of use influence both cost and logistics. Concrete barriers demand heavy equipment and higher upfront investment but offer unmatched longevity. Plastic water-filled barriers, on the other hand, are lighter, easier to deploy, and cost-effective for temporary or shifting work zones. Understanding these differences helps project managers balance safety, budget, and operational efficiency.

Unit Weights & Installation Effort

- Concrete units (e.g. standard 32-in × 10-ft precast): often weigh 3,000-4,000 lbs for a typical 10-foot section. This demands heavy equipment (cranes, forklifts) for transport, positioning, and anchoring.

- Plastic water-filled units: empty weight may be 50-100 lb or more, depending on size (see examples above). Once filled with water or sand, a large unit may weigh several hundred pounds. Because they are lighter when empty, they can often be moved by hand or with minimal equipment.

Cost Breakdown

Costs depend on many things: material, profile, height, span length, whether water-fillable, transport, installation, and maintenance.

Here are ballpark comparisons:

- Concrete barriers: high material cost, high shipping and installation cost. A single precast concrete barrier section might cost several hundred to over a thousand dollars, plus transport and installation.

- Plastic Jersey barriers: lower upfront cost. Some of our units are priced in the ~$170 to $500 range, depending on size and height. (Examples above.) Transportation is cheaper; fewer labour costs for installation.

- Rental vs Purchase: Plastic barriers are more commonly rented for short-term projects; concrete barriers are typically bought for long-term or permanent installations. Rental rates depend on region and project duration.

Lifespan & Durability

- Concrete barriers: Can last 50+ years under good conditions. Cracks or spalling from freeze-thaw cycles, salt exposure, or repeated low-speed impacts may require repair.

- Plastic barriers: UV exposure, temperature extremes, and impact from vehicles can degrade plastic over time. But with good material (virgin plastic, UV stabilized), many plastic models can be reused multiple seasons. Fill/drain plugs, caps, joints might wear/damage and need replacing.

- Environmental factors: Freezing climates may require special design or additives for water-filled units to prevent ice damage; sunlight and UV degrade color and structural integrity over time; chemical exposure, road salt may affect both concrete and plastics differently.

Safety Performance and Statistics

Jersey barriers have a proven track record in improving roadway safety. Studies show that concrete median barriers can reduce cross-median crashes by as much as 93 percent on high-volume freeways, making them one of the most effective tools for preventing catastrophic head-on collisions. While median barrier crashes represent only about 1 percent of total highway accidents, they account for nearly 10 percent of fatalities, underscoring the importance of robust containment systems.

Among the different profiles, the F-Shape barrier has demonstrated better performance than the original Jersey design, particularly in lowering rollover risk at severe impact angles. Plastic water-filled barriers also provide valuable protection when used in lower-speed environments. When properly filled and maintained, they can absorb energy, redirect vehicles, and safeguard both motorists and nearby workers. However, in high-speed corridors with heavy-truck traffic, concrete barriers remain the superior choice due to their greater mass and impact resistance.

Key Highlights

- Safety Shape & Origin: Jersey barriers use a 32-inch profile developed in New Jersey (1955) to lift and redirect vehicles rather than panic-stop.

- Concrete vs. Plastic: Concrete offers much higher impact resistance, making it better for permanent, high-speed, heavy-vehicle scenarios. Plastic (especially water-filled) offers portability, lower cost, and sufficiency for construction zones, lower speed applications.

- Product Examples: We offer plastic barrier models like 32″×72″, 42″×72″, 24″×96″, etc., with prices ranging ~ from US$170 to US$500, depending on dimensions and height.

- Cost & Lifespan: Concrete can last 50+ years, but demands heavy lifting and high installation costs. Plastic barriers need maintenance, are less durable under extreme impacts, and are easier to handle and less costly.

- Safety Stats: Cross-median crash reduction ~93%; rollover risk reduced by F-Shape; median barrier crashes are small in number but high in fatalities (~10 %).

Final Thoughts on Jersey Barriers and Best Practices

Jersey barriers are a cornerstone of traffic safety. Whether concrete or water-filled plastic, a properly selected barrier can dramatically reduce cross-median crashes, prevent serious injuries, and save lives. For highway planners, civil engineers, and traffic safety professionals, the decision should rest on:

- The speed and type of traffic (heavy trucks or high speed favour concrete; lower speed or mixed usage may allow plastic).

- The required height and profile (24-in, 32-in, 42-in, F-Shape, constant-slope etc.).

- The permanence of the installation: permanent vs temporary/construction zones/event use.

- The budget for purchase, transport, installation, and maintenance.

- Local environmental factors: freeze-thaw cycles, UV exposure, visibility, and weight limits.

Make It Work for You

If you're specifying or procuring Jersey barriers for your project, consider Epic Solutions. Our plastic units offer crash-rated designs in multiple heights (24-in to 42-in), spans, and with ballast (water/fill), interlocking features, and modular adaptability. Evaluate total cost of ownership (purchase or rental, transport, deployment, maintenance) and match the barrier profile to your speed, traffic composition, and safety goals.

Contact us for guidance on selecting suitable barriers or getting quotes. We'll ensure the right profile, height, material, and cost for your project.

Recent Posts

-

Controlling a Crowd: The Different Types of Stanchions, Explained

Whenever a big crowd of people gets together, the chance of a crowd surge, crowd stampede, or a crow …Nov 5th 2025 -

Types of Traffic Cones- Sizes, Colors & Safety Uses

Traffic cones are among the most recognizable safety tools on roads, construction sites, and event a …Nov 5th 2025 -

Type III Barricades- Complete Guide to Road & Construction Safety

Work zones demand clear safety measures, and barricade type III designs are vital in guiding drivers …Oct 23rd 2025